From miscellaneous metalwork for water treatment plants to architectural metalwork for shopping centres, offices and car parks.

view sector >

The design, manufacture and installation of motorway sign gantries, cantilevered gantries, footbridges, parapet and EMS platforms.

view sector >

The design and manufacture of galvanised steel and stainless steel products and structures.

view sector >

We have manufactured a wide range of bespoke items to meet our customers requirements. This includes offshore wind, subsea cable laying equipment, ship mounted access and handling equipment...

view sector >

From miscellaneous metalwork for water treatment plants to architectural metalwork for shopping centres, offices and car parks. Steel structures up to 10 tonnes in a single piece or subassemblies for assembly on site.

The design, manufacture and installation of motorway sign gantries, cantilevered gantries, footbridges, parapet and EMS platforms. We are members of the Highways Agency Motorway Gantry Framework working closely with them in the development of highway structures. This is all in accordance with and qualified to NHSS sector 20 as part of our quality management system. Structures can be supplied painted in accordance with sector 19a accreditation. We have also been accredited for our bolting competence and Site installation procedures.

The design and manufacture of galvanised steel and stainless steel products and structures. Many of our products are used in high voltage substations and include structural design checks and manufacturing and assembly drawings as standard.

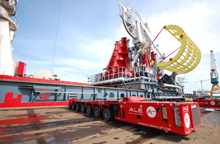

We have manufactured a wide range of bespoke items to meet our customers requirements. This includes offshore wind, subsea cable laying equipment, ship mounted access and handling equipment. We carry out full quality plans and compile extensive quality records to document the fabrication process and provide records for our clients in the form of document packs.

Accredited with ISO 9001:2008 and CE marking of manufactured products to EN1090-1 exc 3, which provides full traceability for all work carried out. Welders are qualified to EN 287 standards and work in accordance to ISO 15614 procedures.

Donyal has successfully created and maintained a healthy client base

across a broad range of businesses. Customer products can be manufactured from

their own designs or Donyal can provide the complete package.

The company employs multi skilled tradesmen and offers an extensive range of ancillary equipment to support its fabrication expertise. Donyal Engineering provides a high quality fabrication service to the manufacturing industry by rapidly responding to customers needs.

The advantage Donyal has over other companies is its in-house capability to handle large fabricated structures. With floor-space in excess of 2000 sqm and craneage up to 10 tons the facility is ideal for the manufacture of sub sections and final assembly. We carry out all types of Non-destructive testing including MPI, ultrasonic and dye penetrant testing and keep records of all welding done.

Click on the links below to download our quality certificate PDFs.